-

Content Count

117 -

Joined

-

Last visited

Posts posted by C. Cordova

-

-

Not sure how much it weighs. I want to try an XLR chasis system instead.

-

-

-

-

You're correct. They are the GAT. My mistake.

-

-

+ 1 for Ross

-

Firstcoues, have you tried those Berger 195s in your 28? I got a 7mm but thinking of turning it in to 28 to shoot those bullets.

You need to make sure your barrel twist is fast enough. Berger recommends 1:8.

-

Is that a Dracos barrel?

-

-

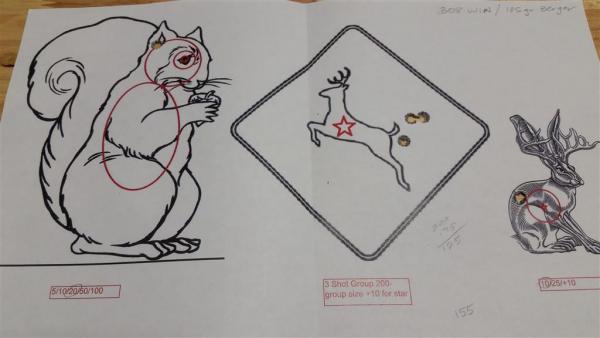

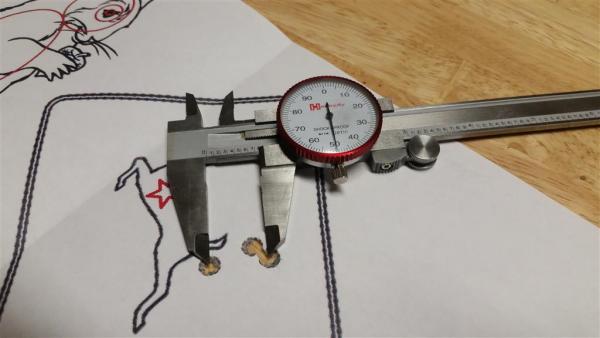

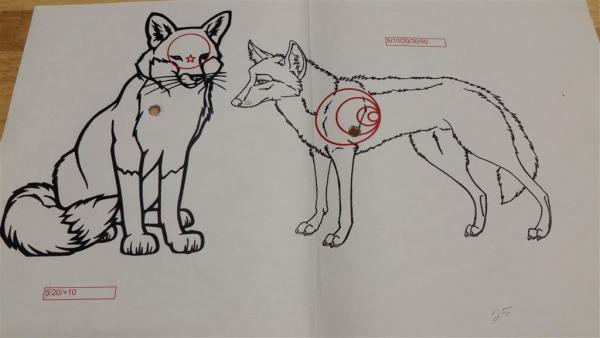

In .308 win/185 gr. juggernaut

-

I use the 210 and cci 250 in my .308 with lapua brass and have also noticed the 210 harder to seat than the cci. Not sure why, but sometimes i'll have to run the 210 through my Lee hand primer 2 or 3 times to get them to fully seat.

-

He looks bigger at first glance, but I got him at 101-5/8 once velvet is shed. Get him on the ground and let's measure him.

-

Looking for short action hinge floor plate bottom metal. Preferably matte black.

-

I went on my first deer hunt when I was 10. We jumped a buck and I watched my dad shoot a coues on a full sprint at 50 yards or so. Two years later I shot my first buck. Looking back, after all these years, I realized what a good shot dad made on that hunt. Many things have changed over the years with big glass, and big caliber rifles, but there's a lot to be said about a good ol .243 and a low power scope.

-

2

2

-

-

-

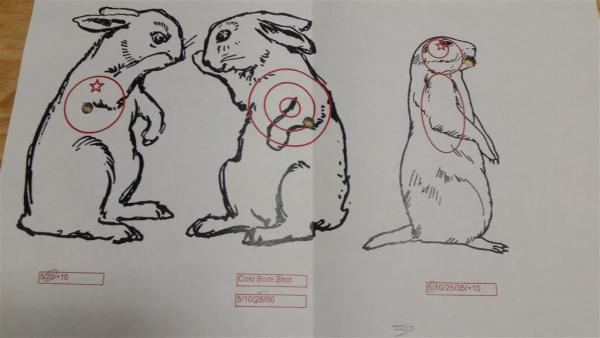

I forgot to mention, you must zero your 300 yard group on the bullseye before starting the process. Oh, and don't shoot off a led sled. The barrel harmonics will behave way differently when you are in the field shooting off a bipod or pack. Get a bubble level too. They really help out at longer ranges.

-

2

2

-

-

One of the question is why did the 2 hotter loads go down in Velocity ?

I have found huge discrepancy in velocity readings when using chronographs. I think it may be due to the lighting conditions changing throughout the day. As pwrguy suggests, I would test group size at 300 yards with a rifle of that caliber. Forget about velocity for now. Find your best load at 300 and then shoot at a long vertical target at 500 ( without turning a turret ) with your aim point at the top of the target. Record the amount of drop to the center of your 500 yrd group into a ballistic calculator ( all variables must be correct, including atmospheric conditions ) and then you will be able to determine a more accurate MV. Once you have your velocity established at this point you can determine the distance your bullet starts to enter the transonic range (1340 Fps ). My guess it will be about 1300 yards or so. Shoot at a "vital zone" sized target at this range and record the amount of MOA or MILs it takes to hit the target. You will then input this data into you ballistic calculator and it will true your drop chart all the way out to your bullets transonic range and give you a very accurate MV. You can also do this at closer ranges than 1300 yards, just know that your drop chart will only be true up to the distance that you true to. I would not worry about velocity so much, as the 300 wm with a 208 gr bullet will be sufficient to kill an elk out to any practical hunting distance, providing shot placement is where it should be. Accuracy is key.

-

1

1

-

-

-

I've had this happen before. The body of the die screws all the way down and the ram cams over before the shoulder of the case makes contact with the part of the die the bumps the shoulder back. Try the redding competition shell holders. They come in a set of 5 with different thicknesses. The thicker shell holders will allow the case to be elevated more and run the case up into the die further.

-

1

1

-

-

Nice video. I like the taller buck. Is he a 4 point on his left side?

-

bump $650

-

-

SOLD. Please delete.

McMillan A5 stock

in Classified Ads

Posted · Report reply

bump